Porcelain Enamel Cover Coats

Release time:

2025-04-25 10:20

Source:

Messi Long

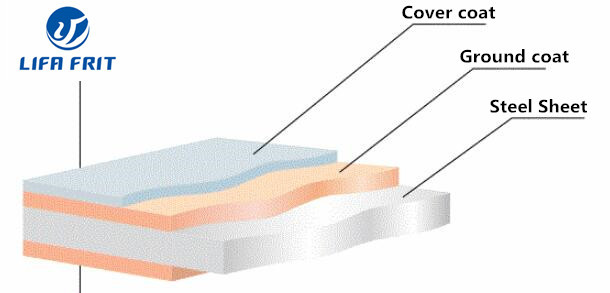

Porcelain enamel cover coat provide the final protective and decorative layer for steel products. These glass-based coatings fuse to ground coat layers at high temperatures, creating durable surfaces with excellent mechanical and chemical resistance.

Common Types:

1, Titanium White Coat - Applied by Titanium white cover coat enamel frit, it can offer superior opacity and whiteness, mainly applied in cookware.

2, Pigmented Coat - Applied by transparent frit with enamel pigments, It provides vibrant colors for architectural and decorative applications.

3, Specialty Coat - Includes high level corrosion resistance or high-temperature resistant formulations. Usually applied in industrial area, such as reactor, pumps etc...

Key Properties:

- Exceptional hardness (Mohs 5-6) and abrasion resistance.

- Chemical inertness against acids, alkalis, and solvents.

- UV stability for long-term color retention.

- Easy-to-clean, non-porous surface.

- Heat resistance up to 450°C.

Applied through wet enamel dipping or spraying and electrostatic powder methods, cover coats complete the enamel coating system while delivering both functional performance and aesthetic appeal. Their versatility makes them ideal for cookware, kitchenware, building facades, and industrial equipment.

Previous Page

Previous Page

RELATED INFORMATION