Catalogue

Ground coat enamel frit for steel

Key words:

enamel frit , porcelain enamel frit , inorganic pigment

Classification:

Product Description

Ground coat enamel frits are directly coated on base metal, with strong adherence and wide range of firing temperature.

Mill addition ratios and requirements of Sb-Mo ground coat frits:

|

Frit |

100 |

Borax |

0.2-0.5 |

|

Clay |

5-7 |

Barium molybdenum |

0.8-1.0 |

|

Quartz |

0-8 |

Sodium nitrite |

0.1-0.3 |

|

Antimony Oxide |

0.8-1.0 |

Water |

55-65ml |

|

Fineness |

0.5~1.0g/150mesh.100ml |

Specific gravity of slip |

160~170g/100ml |

Mill addition ratios and requirements of Ni and Co-Ni ground coat frits:

|

Frit |

100 |

Borax |

0.2-0.5 |

|

Clay |

5-7 |

Sodium nitrite |

0.1-0.3 |

|

Quartz |

0-8 |

Water |

50-55ml |

|

Fineness |

0.5~1.0g/150mesh.100ml |

Specific Gravity of Slip |

160~170g/100ml |

Lifa Enamel Ground Coat Frits Products List:

|

Product Name |

Code No. |

Firing temp (℃) |

Coefficient of thermal expansion(*10-7 ) |

|

High Temp Ni Ground Coat Frit |

EGC-103 |

860-880 |

286.5 |

|

Mid Temp Ni Ground Coat Frit |

EGC-118 |

800-840 |

309.1 |

|

High Temp Sb-Mo Ground Coat Frit |

EGC-105 |

840-870 |

297.1 |

|

Low Temp Sb-Mo Ground Coat Frit |

EGC-124 |

780-820 |

290.1 |

|

High Temp Co-Ni Ground Coat Frit |

2405 |

870-890 |

288.1 |

|

Mid Temp Co-Ni Ground Coat Frit |

2401 |

800-840 |

292.1 |

|

Mid Temp Co-Ni Ground Coat Frit |

EGC-112 |

840-860 |

292.1 |

|

Mid Temp Co-Ni Ground Coat Frit |

1112 |

840-870 |

283.6 |

|

Low Temp Co-Ni Ground Coat Frit |

1122 |

780-820 |

300.5 |

|

Low Temp Co-Ni Ground Coat Frit |

2400 |

760-800 |

322.1 |

|

Anti Fish Scale Frit |

2466 |

840-860 |

320.5 |

|

Anti Fish Scale Frit |

A-7 |

840-860 |

310.5 |

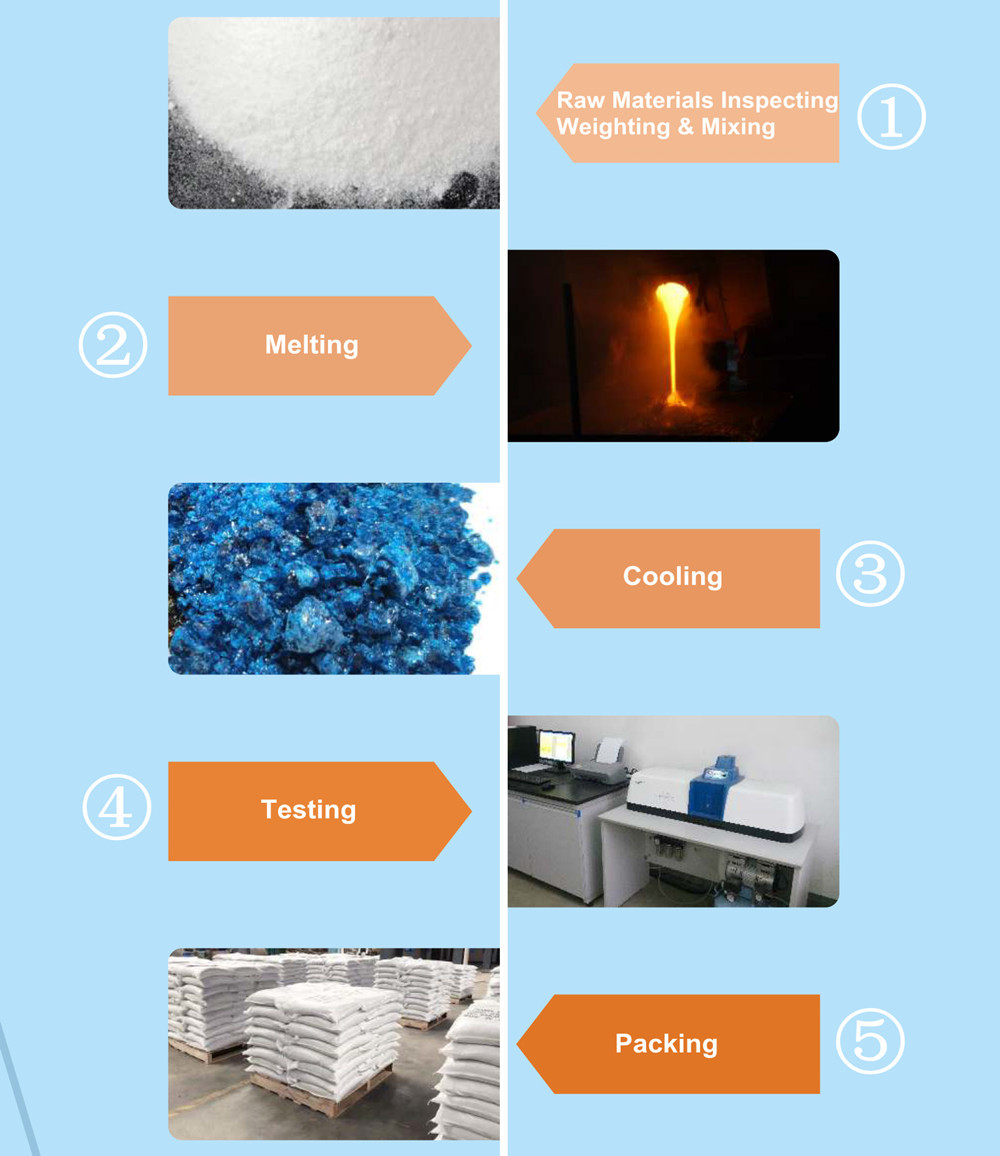

Process of Production

Related Products

Online Message